February 14, Hangzhou’s Xihu District held a major event to accelerate the progress of major projects in the first quarter of 2025. The event saw the concentrated promotion of 19 significant projects, totaling an investment of approximately 10.7 billion RMB, and the signing of 53 key projects with a total investment of 8.42 billion RMB.

Among the most notable projects, Zhejiang University City College (ZUCC) and Zhijiang Laboratory have joined forces to develop the world’s first fully metal 3D-printed satellite, positioning themselves at the forefront of space technology. The project aims to revolutionize satellite production, leveraging 3D printing to reduce costs and production time while enabling more innovative possibilities.

Revolutionizing Space Tech with 3D Printing

“3D Printing, Printing the Future” — this was the title of a book edited by Dr. Tang Huiping, the director of the Advanced Materials Additive Manufacturing Innovation Research Center at ZUCC, over a decade ago. Now, as 3D printing technology advances, it is shaping the future of various industries, including satellite manufacturing.

Dr. Tang explained that the collaboration between ZUCC and Zhijiang Laboratory focuses on creating satellites using 3D printing technology, which significantly shortens manufacturing cycles and reduces costs. Importantly, the technology enables new possibilities in design that were previously unthinkable.

Satellite launch costs are closely tied to both the manufacturing cost and the satellite’s weight. The cost of launching 1 kilogram of payload is 100,000 RMB, so launching a 500-kilogram satellite could cost 50 million RMB. With 3D printing, the use of porous metal materials in satellite structures has reduced their weight by 30%, significantly lowering launch costs.

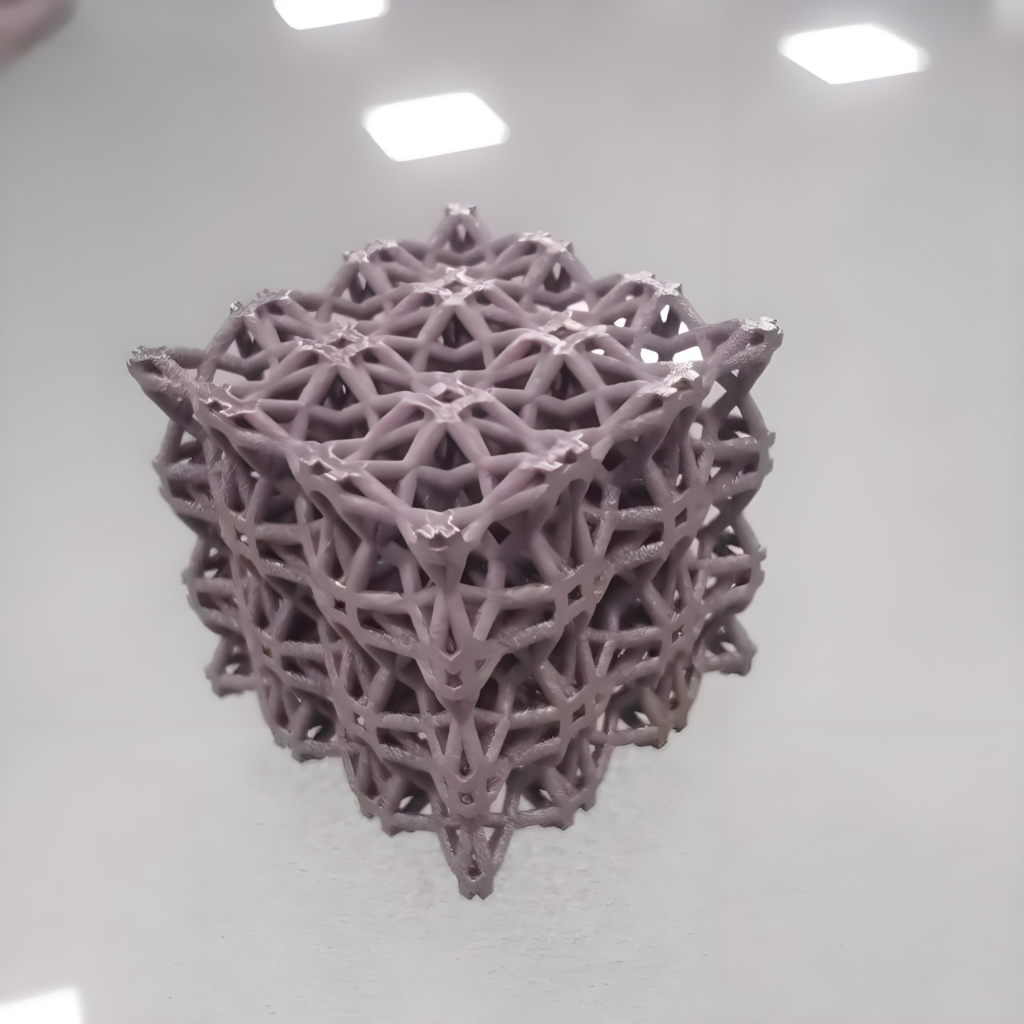

3D printing of porous materials in the main structure of a satellite

Porous Metal Materials: A Game Changer

The key innovation behind the satellite’s structure is the use of porous metal materials, which combine the high strength and toughness of metals with a density lighter than wood. Zhijiang Laboratory’s engineers explored nearly 1 million potential designs before selecting the optimal porous structure for the satellite.

This technology is expected to change the way satellites are developed and produced. Traditional satellite development takes years, but with 3D printing, iterations can be completed in months, reducing production cycles by 50%.

Dr. Tang expressed confidence in the future of the project, stating, “Previously, the research was in the lab phase, but with the strong support of Xihu District, we have entered the engineering stage.”

Strategic Partnerships and Future Vision

In June 2022, ZUCC formed a strategic partnership with Xihu District to co-establish the Advanced Materials Additive Manufacturing Innovation Research Center in the Yunqi Town, focusing on 3D printing technologies for critical sectors like transportation, high-end equipment, biomedicine, and construction.

Reflecting on her experience, Dr. Tang praised the district’s support: “Yunqi Town has provided ‘concierge-style’ services, offering ready-to-use research spaces, free experimental venues, and targeted policy support.”

The team plans to advance both the technological iteration and the construction of production facilities within the year. Dr. Tang envisions building an intelligent future factory, aiming to create a cutting-edge production system across materials, manufacturing, and services.

The world’s first fully metal 3D-printed satellite is expected to launch in 2025, marking a significant milestone for space technology.

The Rise of Low-Earth Orbit

The low-altitude airspace, within 3,000 meters, is seeing various aircraft and manned or unmanned vehicles soaring freely. Above 500 to 2,000 kilometers, low Earth orbit satellites dot the sky, including satellite payloads and platforms. Many of these innovative space technologies are emerging from Hangzhou’s Yunqi Town.

Yunqi Town, named after the cloud computing industry, has become a hub for space and technology startups. With over 300 companies in aerospace, cloud computing, and other cutting-edge industries, Yunqi Town is setting its sights on the vast future of the stars and the sea, blending space, earth, and sea-based ecosystems in a way that promises exciting developments in both technology and business.