Core Summary: Fudan University’s team, led by Peng Huisheng and Gao Yue, has made a groundbreaking discovery published in Nature. Their innovation, the “External Lithium Supply” technology, overturns traditional lithium battery design principles. The team developed an AI-assisted lithium carrier molecule that can non-destructively repair old batteries, extending their lifespan to 12,000–60,000 cycles, which is 10-100 times longer than current lithium batteries. The technology costs less than 10% of the total battery cost and is now entering the industrial verification phase, potentially sparking a revolution in the global battery industry.

1. Technological Breakthrough: From “Scrap Recycling” to “Precision Medicine”

Traditional lithium batteries have limited lifespans due to the continuous consumption of lithium ions in the positive electrode. Once the lithium ion loss exceeds 20%, the battery is considered at the end of its life. However, Peng Huisheng’s team discovered that more than 90% of the components in the battery remain intact when it is scrapped, and only the lithium-ion supply system needs repair.

Innovative Principle:

- The team developed a lithium carrier molecule, Trifluoromethanesulfonyl Lithium (CF₃SO₂Li), which can be injected to precisely replenish the lost lithium ions.

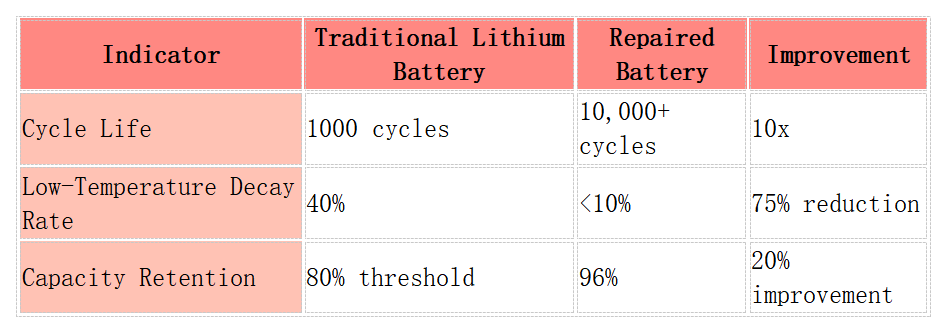

- The breakthrough eliminates the 30-year rule that “the positive electrode must contain lithium,” allowing batteries to be repaired without loss of capacity, restoring them to 96% of their original performance.

- Battery lifespan increases from 500–2000 cycles to 12,000–60,000 cycles (roughly a 30-year lifespan).

Validation Data:

2. Technical Path: A Paradigm Shift in AI + Chemistry

To achieve this molecular design breakthrough, the team created the world’s first organic molecule database for batteries, completing “impossible tasks” through unsupervised machine learning.

AI Design Key Steps:

- Digital Modeling: 15 key parameters, including molecular electrochemical activity and decomposition voltage, are digitized.

- Molecule Fragment Recombination: Over 20,000 organic molecule data sets were used to create a candidate library of over 1 million molecules.

- Prediction and Screening: Algorithms evaluate synthesis feasibility, cost, and compatibility to identify the optimal solution.

Core Breakthroughs:

- Synthesis cost reduced to 1/5 of traditional lithium replenishment agents.

- Air stability increased by 300%, making it operable in standard environments.

- Decomposition byproducts are non-toxic and harmless, overcoming the problem of heavy metal contamination.

3. Industry Transformation: Redesigning a Trillion-Dollar Market

The technology verification indicates that the single repair cost is only 6-8% of the battery’s total cost, with large-scale commercialization potential.

Application Scenarios:

- Power Batteries: Extending electric vehicle battery life to the full lifespan of the vehicle.

- Energy Storage Systems: Reducing grid-scale energy storage costs by 40%, shortening investment return periods to 3 years.

- Extreme Environments: Enabling maintenance-free power supply for polar research and deep-sea equipment.

Industry Impact Predictions:

- Reduce 5 million tons of battery waste annually.

- Lower lithium resource demand by 60%, alleviating supply chain pressure.

- Increase second-life usage rate of power batteries to 95%.

4. Industrialization Progress: From Laboratory to Production Line

The team has established a complete technology transfer chain:

- Molecule Mass Production: A three-step synthesis process has been developed with 99.99% purity.

- Equipment Adaptation: Designed an injection system for soft-pack, cylindrical, and prismatic batteries.

- Strategic Cooperation: Initiated pilot projects with leading companies such as CATL and BYD.

Technology Roadmap:

- Q3 2025: Complete mass-production line verification at the 10,000 Ah level.

- Q1 2026: Establish the first battery repair demonstration center.

- 2027: Achieve full lifecycle management for power batteries.

5. Scientific Community Evaluation & Future Outlook

Nature magazine’s peer review described this study as “redefining the physical boundaries of battery lifespan.” Maria Skyllas-Kazacos, Chair of the International Battery Association, noted that this technology could lead to three major changes:

- Turning batteries from “disposables” into “sustainable assets.”

- Promoting the widespread adoption of the “Battery as a Service” (BaaS) business model.

- Accelerating research into non-lithium cathode materials, fundamentally changing the industry.

With the technology moving toward industrialization, it is expected to reduce global annual battery replacement expenditures by $150 billion and contribute to a 3% reduction in carbon emissions, making a significant impact on achieving carbon neutrality. This original Chinese technology is set to rewrite the global competitive rules in the new energy industry.

(Based on official information from Fudan University and data from Nature journal)